charpy impact test lab report

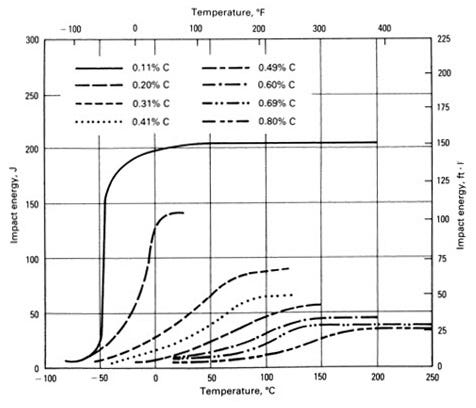

Measures the ability of a material to absorb a sudden application of a load without breaking. From results shown below we determined that the a transition is from ductile failures to brittle failures.

Charpy Test Mechanical Engineering

The impact toughness test of metals provides information on ductile-brittle nature of metallic material upon different temperature.

. The results of the experiment will be used for calculations to fulfil this specific objective. 242393799 Impact Test Lab Report Pdf Objective 1 To Develop An Understanding Of Fracture Toughness 2 To Investigate The Influence Of The Notch Shape Course Hero. Both methods used a data acquisition device DAQ to.

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load 10. Once a specimen reaches the precise temperature it is quickly. In the material testing laboratory a Charpy impact test was performed on three different types hotcoldand steel alloyof steels testing each variety at four different temperatures 32CRT 100C0C and -22C.

California State University Northridge. It is used to determine the toughness of the materials. This test is based on the fact that materials can have two different behaviors.

The Charpy test is a commonly used impact test. Exp 2 Charpy Impact Test Lab Report 12docx. What does the Charpy impact test measure.

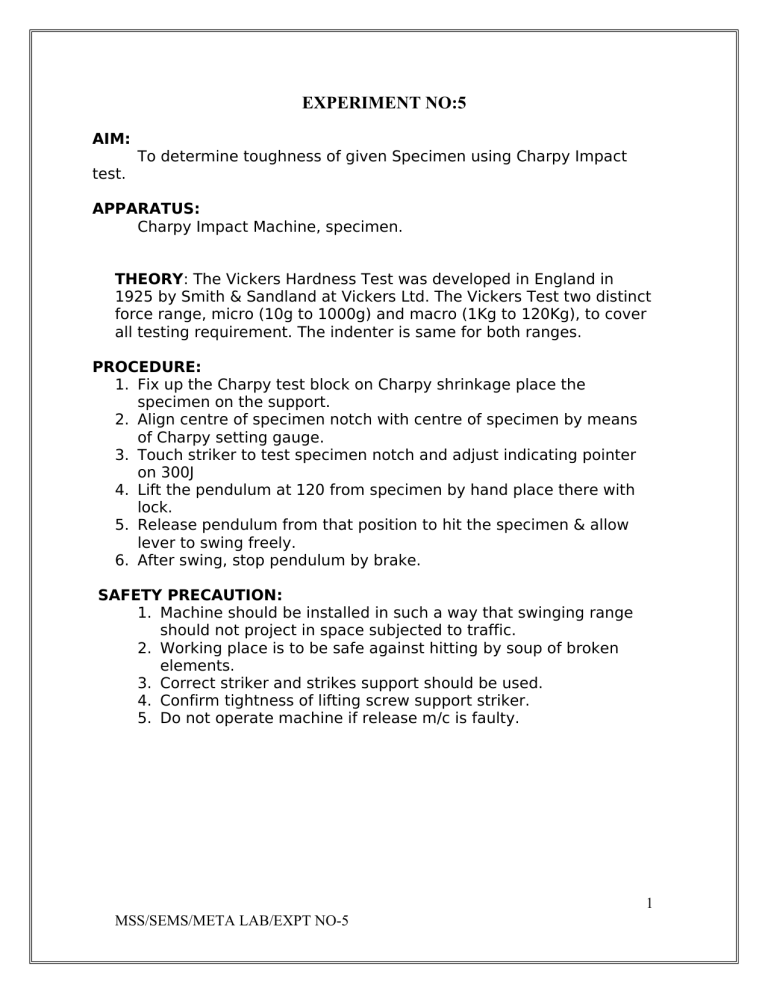

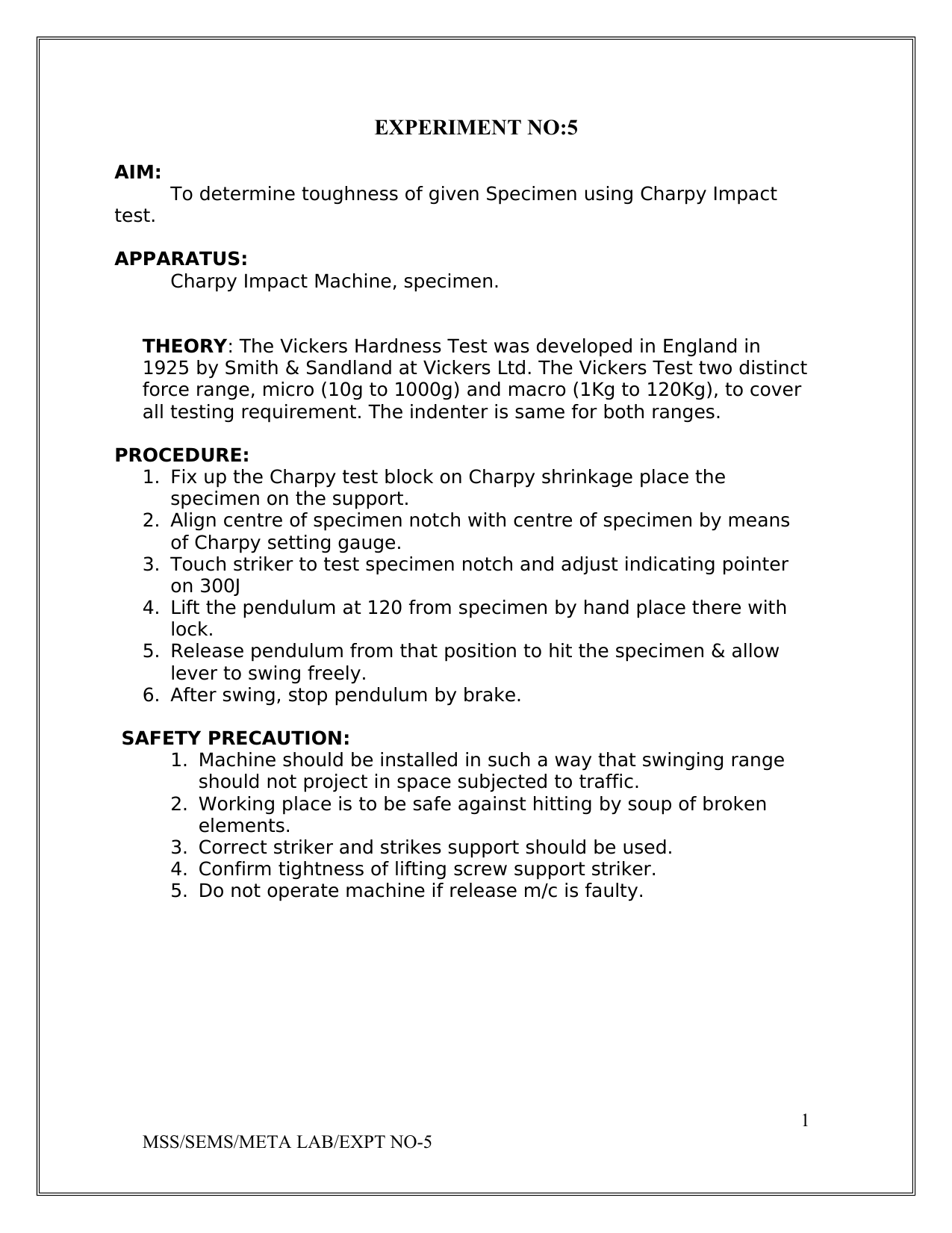

THE UNIVERSITY OF TRINIDAD AND TOBAGO BASc CIVIL ENGINEERING CONS2006. The Charpy impact test also known as the Charpy V-notch test is a high strain-rate test which determines the amount of energy absorbed by a material during fracture. Charpy impact test lab report.

The Charpy impact test is also called as the Charpy V-notch test is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture. One is brittle undesirable in most of the engineering applications. The notches may be.

Up to 24 cash back The charpy impact test is practical for the assessment of fragile metal fracture and is also used as an indicator to determine the appropriate service temperatures. Moreover Izod impact specimen only has a V-notch specimen while Charpy impact specimen has both U-notch and V-notch specimen. Test specimens over a selected range of temperatures attempting to establish a fully ductile test a fully or nearly brittle test and as many temperatures in between as possible.

Specimens were then transferred to a Charpy testing machine to measure the impact energy in ft-lbs. Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. The specimen is usually 55 mm long and has a square cross-section with an edge length of 10 mm.

Furthermore the experiment will test how different temperatures grain boundary orientations and the lattice structure can affect the fracture pattern of the. The lab used two different methods to calculate energy absorbed. There are two state administered tests named Charpy and Izod were planned advertisement utilized widely to gauge the effect vitality.

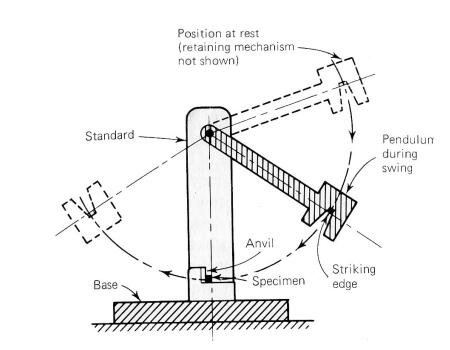

This test consists of striking a suitable specimen with a hammer on a. Materials by measuring the amount of energy absorbed by a specimen as it fractures while. In the Charpy impact test a notched specimen is abruptly subjected to bending stress.

Toughness is the ability of a material to absorb the energy until before it. Test setup and test procedure. The lateral change in dimension of a Charpy impact specimen due to fracture.

In the Charpy test the specimen has a notch cut across the middle of one of its faces. Testing includes sample preparation of three specimens per test and is used primarily for steels which exhibit temperature dependent behavior relating to toughness of the material at. The standard Charpy impact test specimen is of dimension 55 mm 10 mm 10 mm having a notch machined across one of the larger dimensions as illustrated in Fig.

Laboratory Exercise 1 This experiment was designed to demonstrate the performance and interpretation of the Charpy Test. After impacting fracture surfaces were examined for evidence of shear or cleavage failure. In this study three stainless steel specimens at different temperature -78C 80C and 7C respectively were utilized.

Charpy Impact Testing measures the amount of energy absorbed during fracture of a specimen to determine its Ductile to Brittle Transition Temperature DBTT which can be graphed in our report. To do so the materials are tested in many different ways and one of these is the Charpy Impact Test. ABSTRACT The following experimental report will discuss the importance of the Charpy Impact test and how it is used to understand the energy absorption of different materials Steel Aluminium and Brass.

Brittle fracture means that prior the crack there was only elastic deformation and then it broke. The other name of the Charpy impact test is the Charpy V-notch test because of the specimen used in this test cut at a certain depth in V shape. DIN 50115 a 2 mm wide V.

It is placed as a simply supported beam and the impact is applied to the face directly behind the notch using the blow from a swinging pendulum hammer. The most common method for the measurement of impact strength that is Charpy tests is used in this experiment. The Charpy impact test just like any impact testing method determines the toughness of.

Exp 2 Charpy Impact Test Lab Report 12docx. Charpy test result can indicate how brittle the materials are. The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110.

The dimension measured is the width opposite the v-notch see Fig. The Charpy impact test Charpy V-notch test is used to measure the toughness of materials under impact load at different temperatures. CONSTRUCTION MATERIALS I Introduction.

The impact testing machine calculates the energy absorbed which can be converted. Charpy Impact Test Pdf Fracture Strength Of Materials. The Charpy test sample is 10x10x55 mm 3 in size eg.

The test is performed using several machined bar specimens 1cm x 1cm x 55cm with a 2mm deep notch at the middle of a specified flat surface usually a V notch. Ad Low High Energy Charpy Izod Pendulum PlasticsMetals Impact Testers Machines. Lab Report Requirements 1.

The Charpy test specimens were made according to the dimensions of standard ASTM A370. The Charpy Impact Test is one of the impact test methods. V-notch A V-shaped notch 2mm deep with.

-20ºC -10ºC 0ºC 10ºC 20ºC. Abstract This lab report used a Charpy pendulum impact test rig to analyze the differences in energy absorption of a ductile and a brittle specimen. Change in potential energy and strain estimation.

5 Note fracture energy and estimate the brittleness from the appearances of fracture surfaces of the specimens. Impact testing machines india. The specimens are tested at a series of specified temperatures eg.

The Charpy impact test used to determine the resistance capacity of metal steel specimen against sudden impact load of a pendulum which swung from a certain height. The specimens were placed in different temperature baths ranging from -110F -79C to 212F 100C for ten minutes to reach thermal equilibrium. Charpy impact test lab report.

Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces.

Charpy Impact Test Me 220 Mechanics Of Materials Lab Charpy Impact Test Test August 30th 2007 Submitted September 6th 2007 Matthew Course Hero

Charpy Impact Testing Lab Report Pdfcoffee Com

Charpy Test Lab Report Gustavo Salazar Parra 150 W University Blvd Melbourne Fl 32901 Email Gsalazar2007 Fit Edu 12 1 2009 Florida Institute Of Course Hero

Impact Test Lab Report Pdf Title Impact Toughness Of Metallic Materials Objective Study The Principles Of Brittle Fracture In Mild Steels Understand Course Hero

Pdf Comparison Of Impact Duration Between Experiment And Theory From Charpy Impact Test

Pdfcoffee Com Impact Test Lab Report Pdf Free

Lab 3 Devin Gatherwright Iet 307 Portfolio

Impact Test Abstract By Behic Sakar Medium

Exp7 Lab Manual Charpy Impact Testing Metu Department Of Metallurgical And Materials Engineering Studocu

Charpy Impact Test Results On Five Materials And Nist Verification Specimens Using Instrumented 2 Mm And 8 Mm Strikers Unt Digital Library